Products

Elevating mainstream products to build up corprate value

Splitting Machine

GY-1700-MHC

It is a machine that cuts hard/soft FOAM, rubber, and various similar types of blocks as a model that doubles the workable thickness of the machine. It is especially useful when cutting very hard and thick EPE or EPP FOAM.

Features

- All the functions of the "A" series

- Can work up to 210MM in thickness

- Strengthen the power of the roller and knife motor for hard material cutting.

- Automatic knife tension control device.

- It's equipped with an automatic knife escape prevention device.

- It is easy to control the screen with a larger touch screen.

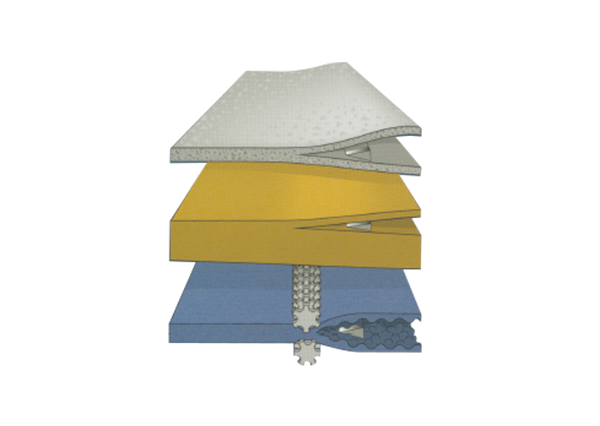

- It can be used both as a normal horizontal cutting and profiling cutting (You can add rollers with customized profiling)

- GY-1700-MHC is a simple exchange system that can quickly replace regular rollers with profiling rollers, minimizing production costs.

Technical data

| Model | GY-1700-HC |

|---|---|

| Available material width | 1600mm(62.9’) |

| Available material thickness | 210mm |

| Available cutting thickness (max) | 200mm |

| Feeding speed | 2-46m/min |

| Close cutting tolerance | ±0.1mm |

| Band knife | 9160 x 100 x 1.2mm |

| Motor mounts | Vertical |

| Roller opening (top / bottom) | 90mm / 210mm |

| Knife wheel drive | 5.5kw(7.5hp) x 2 |

| Auto knife positioning | 0.2kw(½hp) |

| Roller drive | 11kw(15hp) |

| Auto roller positioning | 1kw(1.5hp) x 2, servo |

| Grinder drive | 1.5kw(2hp) x 2 |

| Dust extractor | 2.2kw(3hp) |

| Electrical power capacity | 30kw, Approx |

| Electrical requirements | 220V, 60/50Hz, 3Ph |

| Net / Gross weight | 5100 / 5700kgs |

| Footprint | L5150 x W1850 x H2050mm |

Applications

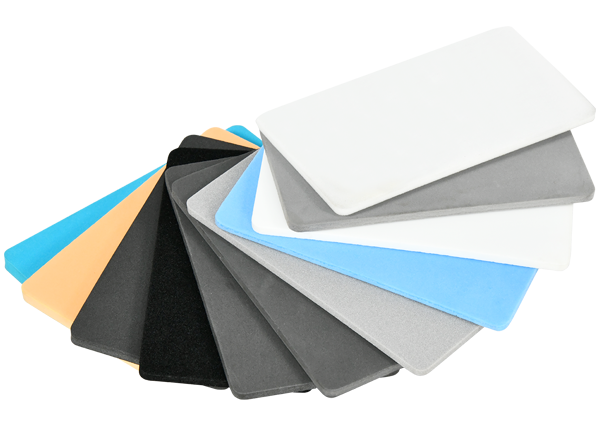

Slabs and rolls from materials with a hardness 10~90 shore, scale A under cold conditions and over 90 shore, scale A under heated conditions such as closed cell rubber, solid rubber(“Neolite”), polyurethane elastomers, moreover PVC floor tiles heated

All kind of rubber products, Neoprene, CR, EPDM, EVA, PU, EPE, PVC flexible foam, Cork and synthetic rubber with similar properties.