Products

Elevating mainstream products to build up corprate value

Splitting Machine

GY-1500/1700-SA

As the most common model, it is a machine that cuts hard/soft FOAM, rubber, and various similar types of blocks. It's equipped with an automatic knife controller.

Features

- Most machine operations are processed by PLC, inverter and touch screen.

- Bandknife is equipped with automatic adjustment. This device automatically uses a bandknife so that the bandknife can maintain an optimal cutting position. A device that controls the position, that is, even when a bandknife is worn due to a grinding operation. Automatically control the position of the bandknife.

- The top and bottom feed rollers continuously supply the ingredients to the band knife.

- The machine has excellent durability, and with a simple and easy control method, hard rubber, hard polyethylene, It cuts blocks and slabs made of very hard materials such as hard PE or hard EVA. A suitable machine.

- You can adjust the speed of the roller depending on the amount of work and materials.

- Height adjustment of the vertical feed roller is possible with a crank wheel or an adjustment panel.

- Bandknife is continuously driven by two wheels.

- The speed of the bandknife can be adjusted depending on the material supplied.

- Six adjustment handles are attached to the back of the housing of the bandknife. This device supports the bandknife so that it is not pushed back by the material supplied during cutting. It plays a role of giving (manual adjustment by the operator)

- Model with very high cutting accuracy (0.1mm tolerance)

- The GY-1700 model has a maximum workability of 200 mm wider than the GY-1500 model.

Technical data

| Model | GY-1500-SA |

|---|---|

| Available material width | 1400mm(55.1’) |

| Available material thickness | 110mm |

| Available cutting thickness (max) | 110mm |

| Close cutting tolerance | ±0.1mm |

| Feeding speed | 2-46m/min(dependent on materials) |

| Band knife speed | 0-2.4m/sec |

| Band knife | 8000 x 100 x 1.2mm |

| Roller opening (top / bottom) | 90mm / 110mm |

| Knife wheel drive | 5.5kw(7.5hp) x 2 |

| Auto knife positioning | 0.2kw(½hp) |

| Roller drive | 11kw(15hp) |

| Auto roller positioning | 1kw(1.5hp) x 2 |

| Grinder drive | 1.5kw(2hp) x 2 |

| Dust extractor | 2.2kw(3hp) |

| Electrical power capacity | 22kw, Approx |

| Electrical requirements | 220V, 380V, 60/50Hz, 3Ph |

| Net / Gross weight | 4600 / 5200kgs |

| Footprint | L4750 x W1850 x H1950mm |

Applications

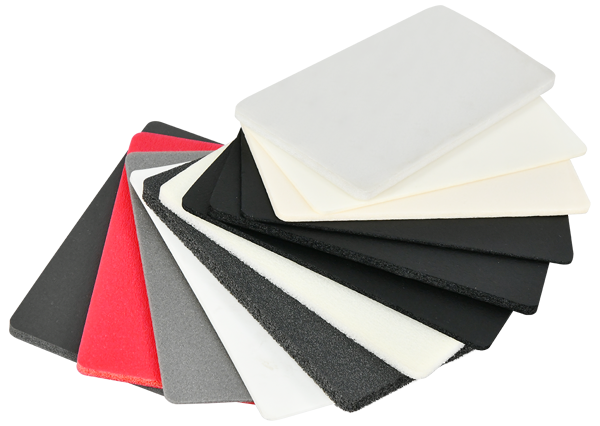

Slabs and rolls from materials with a hardness 10~90 shore, scale A under cold conditions and over 90 shore, scale A under heated conditions such as closed cell rubber, solid rubber(“Neolite”), polyurethane elastomers, moreover PVC floor tiles heated

All kind of rubber products, Neoprene, CR, EPDM, EVA, PU, EPE, PVC flexible foam, Cork and synthetic rubber with similar properties.