Products

Elevating mainstream products to build up corprate value

Vacuum Conveyor Splitting Machine

GY-1400-VC

As an automated system for mass production, you can continue to produce products while circulating multiple blocks simultaneously using loop frames on the drive conveyor. If you install a winder on the conveyor, you can roll it. There are a variety of additional options, especially when GY-400 for side cutting of FOAM blocks and GY-1400FB for adhesion of FOAM blocks are installed together, it becomes a perfect roll product production line. The system can cut materials such as EPDM, open cell, and various soft FOAMs very efficiently and economically by mounting a vacuum conveyor (loop frame) on the cutting unit of the GY-VT model instead of a vacuum table.

Features

- Fully automatic system. A fully automatic production process is possible through the connection between conveyor-powered servo drive technology and PLC controller.

- Vacuum device. Even if the material is not easily fixed on the table due to its light weight, it maintains high cutting accuracy by fixing the material with excellent suction force.

- The length of the conveyor and the size of the machine. Depending on the requirements and applications, it can be made in customized sizes for various work widths, work lengths, and cutting heights.

- Partial speed of the conveyor can be adjusted according to the supplied material and each part of the start/intermediate/finish.

Technical data

| Model | GY-1400-VC |

|---|---|

| Available max material width | 1400mm(55.1’) |

| Available max material thickness | 300mm |

| Available max material length | Customized conveyor line |

| Available max cutting thickness | 80mm |

| Close cutting tolerance | ±0.1mm. |

| Feeding speed | 2-40m/min(dependent on material) |

| Motor mounts | Vertical |

| Knife opening from vacuum conveyor | 300mm |

| Roller opening from knife | 80mm |

| Knife wheel drive | 7.5kw(10hp) |

| Knife positioning (up/down) | 2kw, servo (brake type) |

| Auto knife positioning | 1kw(1.5hp) |

| Roller drive | 1kw(1.5hp), servo |

| Auto roller positioning | 0.4kw(½hp), servo |

| Conveyor drive | 2.2kw(3hp) x 4, servo |

| External vacuum (partial) | 3.5kw(5hp) x 2 |

| Grinder drive | 1.5kw(2hp) x 2 |

| Dust extractor | 2.2kw(3hp) |

| Electrical power capacity | 33kw, Approx. |

| Electrical requirements | 220V, 60/50Hz, 3Ph |

| Net / Gross weight | 5900 / 6700kgs |

| Footprint | W5400 x H2050mm, Conveyor line 10m (standard) |

Applications

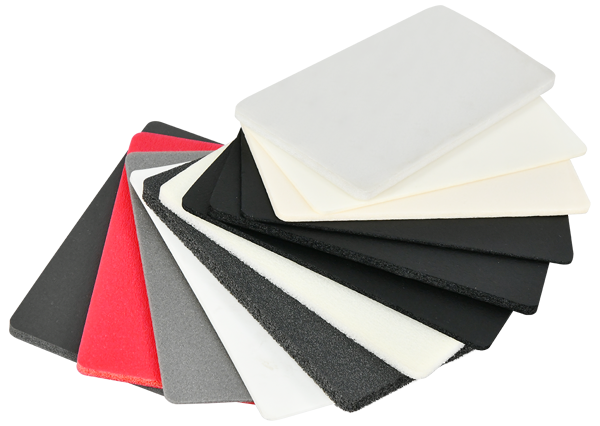

Blocks made of expanded rubber ('Neoprene'), open and closed cell foam, CR, EPDM, PU bun, PE foam, Re bonded PU and synthetic materials with similar properties

Especially, very effective for cutting Open cell foam